The first European standard to deal with the testing of filters for ventilation was established in 1980 named EUROVENT 4/5created to classify coarse and fine filters. It did not specify air flow rates and final pressure drop but only average point efficiency (classifying EU5 to EU9) and arrestance for coarse filters (EU1 to EU4).

The rule was amended by taking the name of EUROVENT 4/9: therefore defined the use of a very fine oil mist generated by compressed air called DEHS to measure particle efficiency in the range of 0.2 to 5 microns.

The end of the 1990s and the beginning of the new millennium saw the birth of the new standard EN 779:

EN 779 was published by the European Commission for Standardisation (CEN).

It took the EUROVENT 4/5 standard as a basis but used ASHRAE standards 52-68 and 52-76 as a reference. However, it did not include tests on fractional efficiency measured over predetermined particle size ranges.

It is intended to determine: the arrestance of filters using synthetic powder by a gravimetric method, the efficiency of fine filters is determined by the particle count method.

The standard has a dual classification system using letters and numbers: G and F for coarse (G) and fine (F) filters respectively, followed by numbers from 1 to 9.

The test comprises two methods: a gravimetric one, suitable for coarse filters to detect the performance of filters designed to treat mostly recirculated air, usually richer in lint and fibres.

The fractional type test is performed for filters with medium to high efficiencies.

The gravimetric method makes use of standard synthetic powder while the fractional method is performed with a particle counter by measuring the concentration of the tracer (DEHS-LATEX) upstream and downstream of the filter in the 0.4 μm particle size after loading the filter with synthetic powder (ASHRAE 52.2).

The former is therefore more suitable, within certain limits,

The tests allow the arrestance of coarse filters and the efficiency of medium and fine filters to be determined:

- pressure drop pattern with clean filter

- pressure drop trend as a function of dust accumulation

The arrestance or separation efficiency does not remain constant with the progressive accumulation of dust on the filter: it may increase or decrease or present a mixed trend according to its Characteristics

EN 779

In 2002, EN 779 underwent its first amendment in order to bring tests in the field of indoor air quality in line with environmental protection.

It is therefore determined that the test rig is the same as the previous one but that the fractional efficiency (using DEHS oil mist) is calculated from the previously identified average point efficiency.

Therefore, after a series of tests on different test laboratories, the fractional average efficiency value at 0.4 microns was identified and became the reference standard for all measurements.

The DEHS used for the test is easy to generate while maintaining its concentration and size characteristics during testing. It can also be used either electrostatically charged or in an electrically neutral phase.

Its density of about 1 g/cm3 makes it suitable for achieving equivalent values between aerodynamic and geometric dimensions.

The procedure for performing the test therefore consists of four steps:

- Measurement of pressure drop at the ends of the filter using filtered air at 4 different flow rates.

- Determination of efficiency at 0.4 microns by measuring upstream and downstream of the filter using a particle counter.

- Measurement of the arrestance, pressure drop and weight of particulate matter retained through the gradual feeding of synthetic powder into the filter.

- Determination of the class according to the average performance measured.

The EN 779-2002 standard paid attention to the influence of electrostatic effects on the filter media itself. To this end, it is mandated that the electrostatic charges present be removed using isopropanol and that the filter be tested again after treatment.

The standard identifies 5 ranges of size intervals to be measured in a size range between 0.2 and 3 microns; considering the reference value of 0.4 microns, EN 779-2002 classifies filters in

GROSSOLANI (type G) efficiency < 40% at 0.4 microns, final pressure drop 250 Pa.

FINI (F-type) efficiency >40% at 0.4 microns, final pressure drop 450 Pa.

The EN 779 2002 classification system introduced and the methods used to perform the tests only make it useful to compare similar products with each other but do not consider the actual performance of the product in the field.

It is very important to consider that the actual performance of filters in operation is influenced by many factors, many of which cannot be reproduced in the laboratory.

Based on the above considerations, EN 779-2002 is revised in 2012 by introducing the minimum efficiency requirement for fine filter classes (F7-F8-F9). This is measured between INITIAL EFFICIENCY with a new filter with DEHS, INITIAL EFFICIENCY measured on a sample of electrostatically "discharged" material and MINIMUM EFFICIENCY between measurements with a dirty filter.

An intermediate class was created for classes F5 and F6, renamed M5 and M6 indicating 'medium' filtration (as opposed to coarse and fine). This is due to the fact that for these two efficiency classes, the standard does not provide for the measurement of minimum efficiency or even the test on an electrostatically discharged filter.

| CLASS EN779 - 2002 | Group | Max Pressure Drop | Average Arrestance (Am) of synthetic dust (%) | Average Efficiency (Em) of 0.4 micron particles (%) |

| G1 | Coarse | 250 Pa | 50 < Am < 65 | – |

| G2 | 65.01 < Am < 80 | – | ||

| G3 | 80.01 < Am < 90 | – | ||

| G4 | Am > 90.01 | – | ||

| F5 | End | 450 Pa | – | 40 < Em < 60 |

| F6 | – | 60.01 < Em < 80 | ||

| F7 | – | 80.01 < Em < 90 | ||

| F8 | – | 90.01 < Em < 95 | ||

| F9 | – | Em > 95.01 |

| CLASS EN779 -2012 | Group | Final Pressure Drop | Average Arrestance (Am) of synthetic dust (%) | Average Efficiency (Em) of 0.4 micron particles (%) | Minimum Initial Efficiency of 0.4micron particles on FLAT SHEET (%) | |

| G1 | Coarse | 250 Pa | 50 < Am < 65 | – | – | |

| G2 | 65.01 < Am < 80 | – | – | |||

| G3 | 80.01 < Am < 90 | – | – | |||

| G4 | Am > 90.01 | – | – | |||

| M5 | Medium | 450 Pa | – | 40 < Em < 60 | – | |

| M6 | – | 60.01 < Em < 80 | – | |||

| F7 | End | 450 Pa | – | 80.01 < Em < 90 | + | > 35% |

| F8 | – | 90.01 < Em < 95 | > 55% | |||

| F9 | – | Em > 95.01 | > 70% |

ISO 16890

In June 2018, the new standard UNI EN ISO 16890:2017 was introduced, approved with 100% of votes from participating countries by the CEN and ISO technical committees.

This standard replaces the current European standard EN 779 and ASHRAE 52.2, predominant in the USA, with the aim of creating a single worldwide standard related to filter performance against three different particulate fractions with a percentage figure identifying the efficiency of the filter element

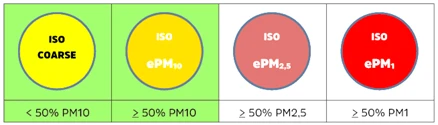

In ISO 16890:2017, filters will no longer be divided into coarse efficiency classes (G), Medium (M) or Fini (F), but they will be divided into four classes:

ISO Coarse, ISO ePM10, ISO ePM2,5 and finally ISO ePM1.

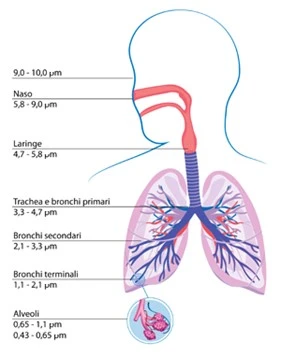

The particle size of fine dust is divided into categories identified by the abbreviation PM (Particulate Matter, i.e. small particles)

- PM10 - particulate matter consisting of particles smaller than 10 µm and up to 0.3 µm

- PM2.5 - fine particulate matter with a diameter of less than 2.5 µm and up to 0.3 µm

- PM1, - particulate matter with a diameter of less than 1 µm and up to 0.3 µm

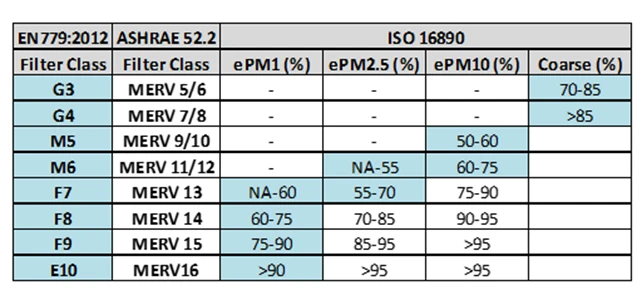

The table shows the differences and classification correlation between EN 779 and ISO 1690 2017

| UNI EN 779:2012 | UNI EN ISO 16890:2017 | ||||

| Iso Coarse | ePM10 | ePM2.5 | ePM1 | ||

| Gross | G1 | 40% | – | – | – |

| G2 | 70% | – | – | – | |

| G3 | 80% | – | – | – | |

| G4 | 90% | – | – | – | |

| Medium | M5 | – | 50% to 55% | 10% to 35% | 5% to 20% |

| M6 | – | 65% to 70% | 50% to 55% | 20% to 40% | |

| End | F7 | – | 80% to 85% | 70% to 75% | 60% to 65% |

| F8 | – | 90% to 95% | 80% to 85% | 75% to 80% | |

| F9 | – | 95% to 100% | 90% to 95% | 85% to 90% | |

Following joint studies by the scientific, medical and WHO (World Health Organisation) communities, which found and confirmed the increasing danger to human health caused by particles smaller than 1 micron in the environment.

It can therefore be said that ISO 16890:2017

classifies filters according to the atmospheric particles retained.

The particle size of fine dust is divided into categories identified by the abbreviation PM (Particulate Matter or Particulate Matter, i.e. in small particles).

- PM10 - particulate matter consisting of particles smaller than 10 µm and up to 0.3 µm

- PM2,5 - fine particulate matter with a diameter of less than 2.5 µm and up to 0.3 µm

- PM1particulate matter with a diameter of less than 1 µm and up to 0.3 µm

The table below compares the different test methods between EN 779 and ISO 16890

| UNI EN 779 :2012 | UNI EN ISO 16890:2017 | |

| Air flow rate used for the test | From 850 m3/h (V= 0.24 m3/s) to 5400 m3/h (V= 1.5 m3/s) | From 900 m3/h (V= 0.25 m3/s) to 5400 m3/h (V= 1.5 m3/s) |

| Efficiency classes analysed | G1-G2-G3-G4-M5-M6- F7-F8-F9 | ISO Coarse - ePM10- ePM2,5- ePM1 |

| Efficiency | Minimum (ME) for classes F7-F8-F9 | Average (EA) between initial efficiency (Ei) and discharged efficiency (Ed) |

| Size of test contaminant | 0.4 µm | 0.3 µm to 10 µm (depending on class) |

| Discharged efficiency (Ed) | Tested on class F7-F8-F9 media samples with liquid isopropanol | Tested on complete filter with isopropanol vapours |

| Aerosol used for the test | DEHS (Octyl Sebacate) | DEHS for powders from 0.3 µm to 1 µm KCL (potassium chloride) for powders from 2.5 µm to 10 µm |

| Powder used for coarse filter tests and energy efficiency | ASHRAE | ISO fine A2/C |

| Dust accumulation | Classes G1 to G4 up to an ultimate pressure drop of 250 Pa Classes M5 to F9 up to an ultimate pressure drop of 450 Pa | PM10 < 50% - Final pressure drop of 200 Pa PM10 ≥ 50% - Final pressure drop of 300 Pa |

| Amount of powder fed per test | 70 mg/m3 | 140 mg/m3 |